DKM is specialized in injection molding production lines. PET preform molding production line is one of the most important production lines. And here please allow me to introduce DKM PET preform molding production line.

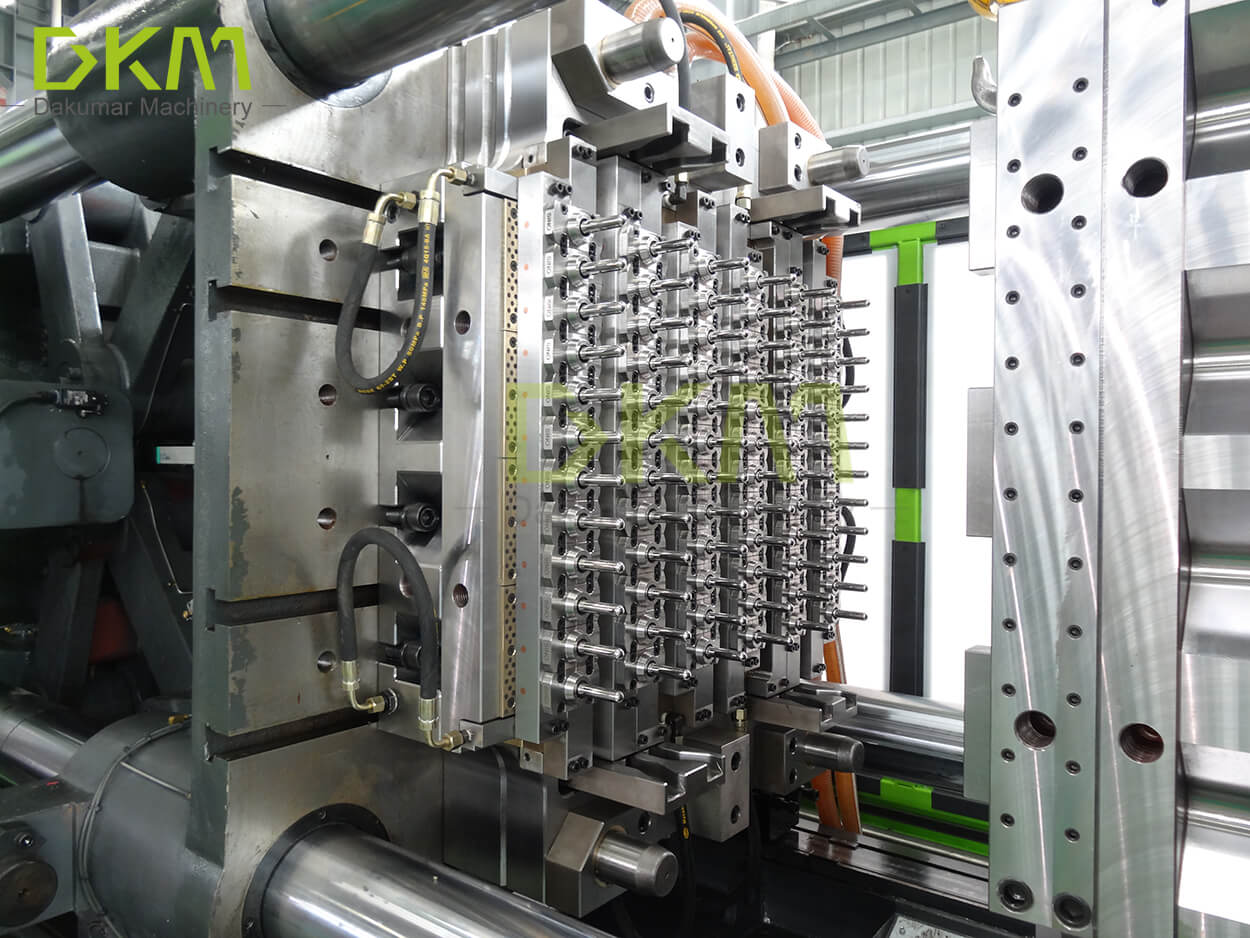

-PET preform moulds

With over 20 years' research and development, we are now very professional in making different cavities PET preform moulds, such as 8 cavities, 16 cavities, 32 cavities, 48 cavities, 64 cavities, 72 cavities… Meanwhile, PET preform moulds has different standards of neck diameters. DKM has made PET preform neck diameter 28mm, 32mm, 55mm…

Mould steel: S136

Injection gate: full hot runner valve gate

-DKM PET injection molding machines

DKM has injection molding machines from 80T to 4000T with different types, like servo injection molding machine, high speed injection molding machine, PET injection molding machine, PVC injection molding machine… DKM provides customers different types and different tonnages injection molding machines to meet their production needs.

DKM has developed a machine specially designed for PET preform molding, which has the characteristics of high speed, high efficiency, high stability and high energy saving.

1. PET special screw;

2. Larger injection capacity can meet the requirements of PET injection pressure. Generally, PET preform molds do not require higher clamping force, but require higher machine injection pressure;

3. Servo system to support higher injection pressure;

4. The hydraulic motor can provide more torque for the machine to meet the particularity of PET material;

5. Oil pump, servo motor and servo driver can reasonably control the cycle period.

DKM production line services range from the customization of machines, molds and auxiliary equipment to the layout of the plant, water and electricity layout and installation, to on-site construction and commissioning. The customer can entrust and deliver to DKM with full authority. DKM team's complete service and professional technical support will help. The customer completes the installation and commissioning of the production line in the shortest time until smooth production.