Since 2000, SINOPK Package Mold, one division of SINO MOULD, had already delivered thousands of multi-cavities high precision plastic cap molding solution to leading molding company in Europe, North and south America, Australian, Asia and Africa. With a high attention on innovation and development, we are devoted to providing a complete fine cap and closure moulding line and intend to make it more valuable.

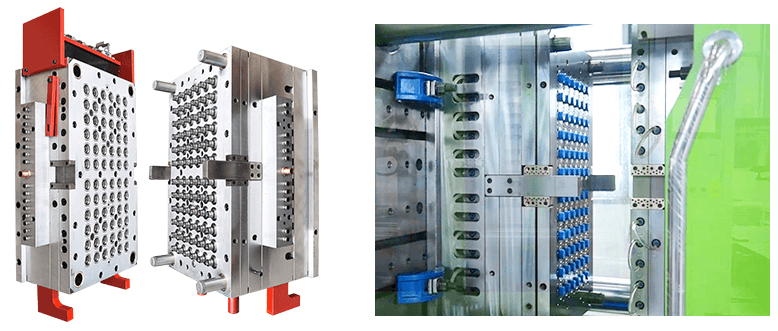

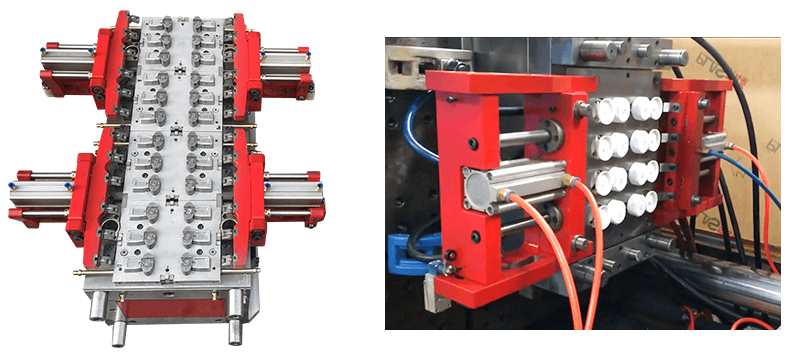

Multi-cavities mineral water cap molding solution (Max. Up to 144cavities)

Fast cycling and high speed closure molding with collapsible core design

Flip top cap moulding solution with/without auto close system

Cap and closure mold with inside-closing system

Unscrewing cap and closure system

Bump-off cap and closure solution

Based on well-known manufacturing experience and continues years research &development, SINOPK attaches important eye on innovation technology and are also forced on fast cycle time optimization molding solution. In each project, SINO PEOPLE keep this in mind and take into actions. Besides, good fitting between cap and bottle is also key point. Below shows some characteristic cap and closure injection moulding projects for your reference.

Mineral Water Cap Molding Solution

Professional cap design

Full automatic unscrewing solution for deep screw

Multi-cavity max. 144 cavities

Optimal cooling

Best neck fitting with preform

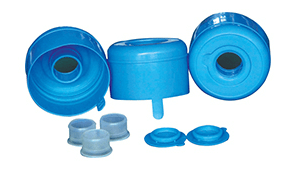

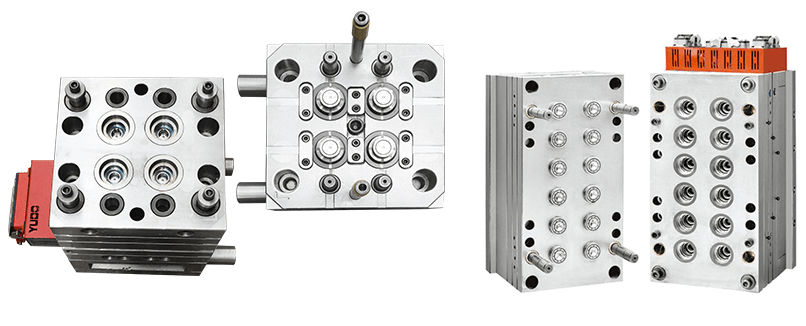

Five Gallon Cap Molding Solution

Steel Stavax S136

Longer mould life with stable production

Optimal cooling for fast production

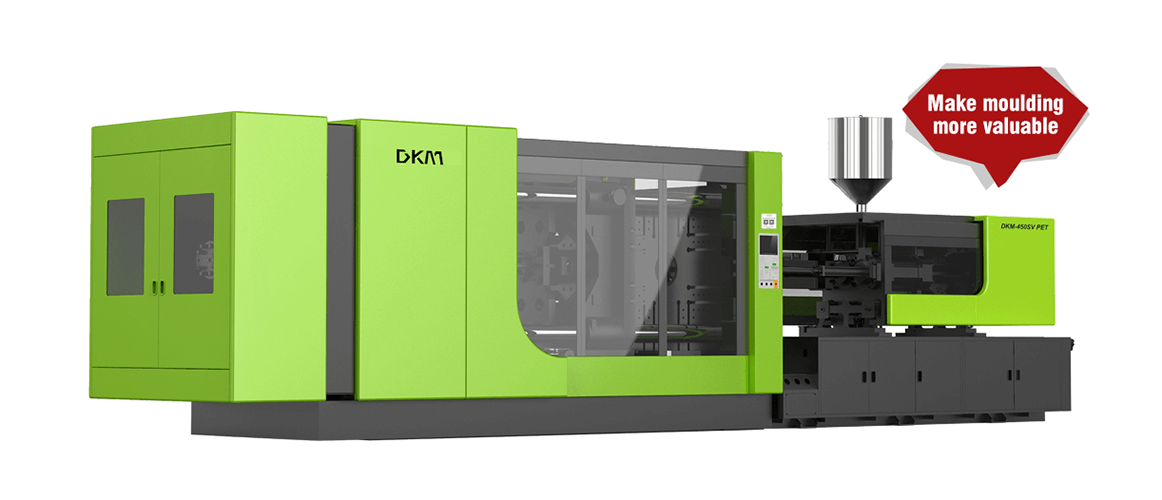

Suitable Machine for efficient production

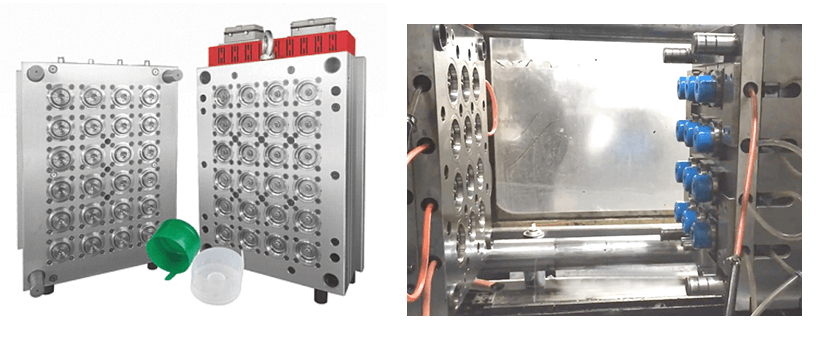

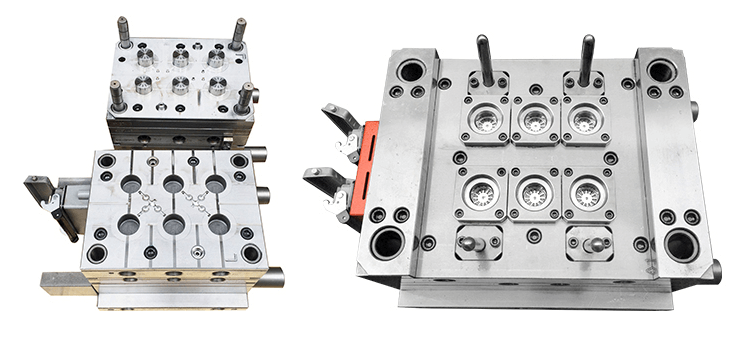

Flip Top Closure Molding Solution

Designed with/without auto-close system

Optimal mould design for shortest cycle time

Suitable flip top cap making machine

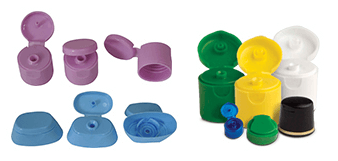

Oil Cap Molding Project

Optimal oil cap design for better quality

Optimal mould design for shortest cycle time

Keep the rigorous QC for the whole line

Best machine for oil cap to make fast and stable production

Medical Capsule Closure Molding Project

Optimal medical cap design

Optimal mould design for best molding

Suitable machine for efficient production

Complete auxiliary equipment optional for the final medical caps

Other Related Service

Except cap and closure injection molding service, SINOPK could also provide other related machines, such like, high speed capping machine, cap uncovering machines, cap ring cutting machines, closure closing machines, cap folding edge machines, machines and so on.

What Do Your Prepare?

10-20 pieces cap samples OR 3D closure drawings

Cap Bottle mounting sample OR 3D drawings

Tell your schedule production plan

What SINOPK Provide?

A complete cap and closure detail solution (Quotation, Suitable equipment choice, technical suggestion, factory layout plan....)

Engineer service to local factory for installing and adjusting

Fast cycle time and high volume suggestion

High efficiency cap injection molding training

Maintenance knowledge course